How can the workplace be optimally adapted to the employee working there? What working environment does he or she need to find so that he or she feels comfortable and can work efficiently without being too stressed? And which work equipment supports him or her in the best possible way? Workplace handling at ELABO deals with precisely these questions and deals in several respects with the optimum design of the workplace depending on the employee who works there.

Ergonomics as a central aspect in the planning phase

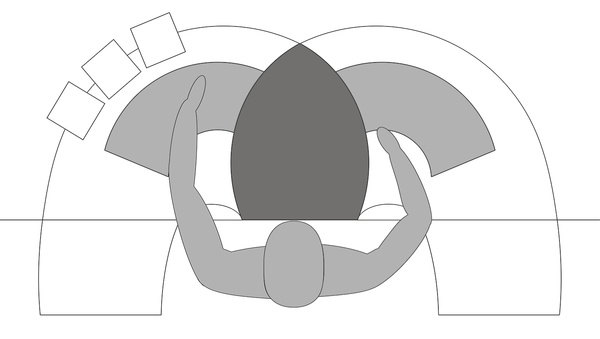

And at ELABO, this begins as early as the planning phase of a workplace. Even before the order is placed, it can be examined in an ergonomics check using virtual reality. Gripping areas, tool arrangement and the positioning of the containers can be simulated. In this way, ELABO ensures that the ergonomic design of the workplace plays a central role from the very beginning.

Ideal workstation settings for each employee

Once the workstation is used, it identifies the employee at the start of work and adjusts to the optimum working height. This depends both on the size of the employee and the workpiece to be handled.

Dynamic adjustment of lighting and working height

The lighting of the workplace is also elementary in terms of ergonomics. This, too, always adapts to the individual preferences of the employee and can be individually controlled depending on the work step. The optimal illumination of the workplace and the workpiece is easy on the eyes of the employee and reduces stress. In conjunction with an test plan in the Elution® factory software, the workstation also knows exactly which working height and lighting is optimal for the respective work step (keyword "focusing"). Therefore, dynamic adjustment during the assembly process is also possible - all automatically.

Focus on assembly work – without heavy lifting

In order not to have to lift heavy workpieces, the employee is relieved by mobile workpiece carriers in the FIM solution (Flexible Individual Mounting), for example. With this solution, the workpiece to be assembled proceeds through the individual production steps on a mobile table. This means that the employee does not have to lift the sometimes heavy workpieces and pushes the table into the correct position without effort. Alternatively, this process can also be performed by automated guided vehicles (AGVs). In this way, the employee can always concentrate on his or her actual assembly work.

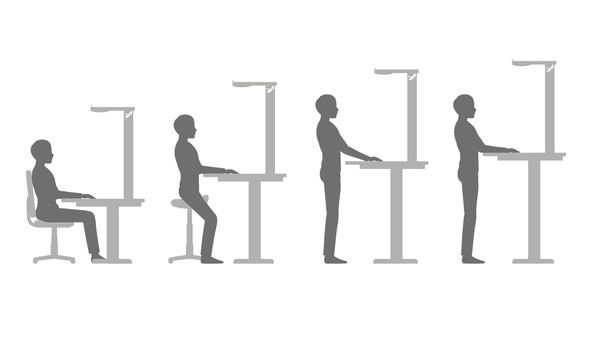

Upgrade to a height-adjustable workplace

We offer you a cost-effective way to design the workplaces in your company ergonomically. By switching to height-adjustable workplaces, you not only increase the well-being of your employees, but also proactively counteract absences due to illness. Simply retrofit your existing Inform, Primus One® or Primus Basic system table. In the video you can see how simple and fast a transformation works.